New Gen Inverter Plasma cutter for New Gen Steels

What is plasma and how does the plasma cutting process work?

- Plasma is the fourth state of matter but we need to define it in accordance with its purpose when working with plasma cutters. In that sense, plasma is an electrically heated gas that is created by heating the air to extreme temperatures making it electrically conductive or in other words, it becomes ionized gas.

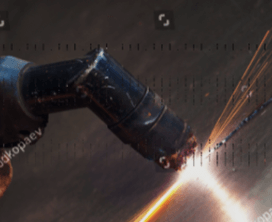

- This ionized air/gas under pressure becomes a plasma cutting arc that you use to slice the metal like butter.

- Inside the plasma torch, there is an electrode and it receives the electricity from the machine. The compressed gas or air is also supplied through the plasma torch and once the electrode initiates the arc with the conductive metal (work-piece), the plasma gas arc is born.

- At that point, the compressed gas starts conducting the electricity and becomes plasma that bursts under high pressure through the small opening at the end of the nozzle. This electrically conductive air is a plasma arc that cuts the metal thanks to the incredibly high temperature that is concentrated in that small dot where the plasma touches the metal piece.

Different types of plasma cutters based on cutting techniques

- Inverter plasma cutters

- Configurations of CNC Types of Plasma Cutting

- 2-dimensional / 2- axis plasma cutting

- 3-dimensional / 3+ axis plasma cutting

Applications

- Manufacturing

- Pharmaceutical

- Oil/gas

- Arms industries

Advantages

- More Versatility and compatible with a wide range of materials.

- Ease of Use. These plasma cutters are portable and you can easily move this wherever the job demands.

- Fast Cuts

- Precision Cut Quality

- Lower Price

- Piercing Speed

- Safety

- Curves, odd shapes, and multiple intersecting cuts can all be drawn by a precise beam

How to select a plasma cutter?

A few questions you need to be asking yourself, before deciding on a plasma cutter

- Manual or mechanized???

- Required Cut thicknesses and quality???

INTELLI Inverter Plasma cutter 40

INTELLI Plasma 40 is an Inverter Type Heavy Duty Plasma Cutter which can cut up to 15 mm thickness with ease. Inverter technology ensures up to 50% power saving than traditional MIG Welders. INTELLI Plasma allows a rapid, distortion-proof cutting of all conductive materials such as steel, stainless steel, galvanized steel, aluminum, copper, brass, etc.