Know about Dry & Wet type Spray Paint Booth

Spray Paint Booths are essential tools in the painting industry, delivering outstanding paint finishes while putting operator safety and environmental standards first. To make an informed decision based on individual requirements, it is critical to understand the key differences between dry and wet type spray paint booths.

Dry Type Spray Booths: Precision Without Water

Paint arresting filters are used in dry type spray paint booths to capture overspray paint and surplus paint fumes, assuring a thorough paint finish. Here’s an overview of their merits and demerits:

Merits

- Lower initial costs for equipment and installation.

- Potential for powder coating finish reclamation from filters.

- Reduced maintenance expenses.

- Environmentally friendly due to minimal chemical usage and waste disposal.

Demerits

- Fixed production rate.

- Replacement of physical filters leads to operational costs.

- Limited overspray handling capability.

- Increased manpower required for cleaning and maintenance.

Wet Type Spray Booths: Efficiency Through Water

Wet spray paint booths use a water curtain or water to collect overspray, resulting in sludge that is handled and disposed of properly. Consider the following merits and demerits.

Merits

- Efficient handling of various paint types and high production rates.

- Durability and efficiency in capturing overspray.

- Safe and contained sludge collection, reducing airborne pollutants.

- Customizable sludge removal systems for streamlined operations.

Demerits

- Ongoing operational costs for water treatment chemicals.

- Higher initial investment in equipment and installation.

- Space requirements for sludge removal systems.

- Potential humidity issues affecting paint quality.

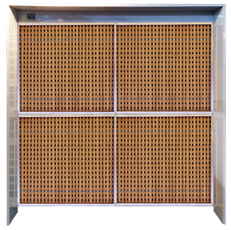

ATS ELGI’s Dry Type Liquid Spray Paint Booth: Innovation in Action

A renowned spray paint booth manufacturer, ATS ELGI, provides cutting-edge solutions such as the Dry Type Liquid Spray Paint Booth. Key advantages include:

- Paint dry arresting without the use of water or chemicals.

- Utilizes advanced synthetic glass fiber filters for efficient paint capture.

- Easily changeable, high-quality filters.

- Powerful extraction system ensuring clean air output.

- Perfect for a variety of paint jobs, increasing adaptability.

Conclusion: Elevating Painting Standards with ATS ELGI

ATS ELGI remains at the forefront of spray paint booth technology, revolutionizing painting processes for cleaner, safer, and more productive work environments. ATS ELGI continues to make major contributions to the progress of the industry by promoting innovation.

Experience the future of painting technology by exploring ATS ELGI’s extensive selection of spray paint booths. Visit ATS ELGI’s official website for more information about their products and solutions. With ATS ELGI’s experience and creativity, you can make an informed decision and raise your painting standards.