All You Need to Know About CLMS

What is CLMS?

The Centralized Lubrication Management System (CLMS) supplies individual lube points or groups of points with precisely metered amounts of lubricant from a single location to meet their varying needs.

This system is designed to increase the efficiency of the oil change process and provides full visibility on the quantity of oil dispensed.

Results end solution to the customers like.,

- No wastage – No spillage

- Supports more than 5 grades of oil

- Time management

- Increases workplace efficiency

Advantages of Centralized Lubrication Management System

- Ease of Use -Its simple and in-built a product for users.

- Increase in Productivity – Which improvement in the efficiency and output .

- Oil Accountability – The processes & measures in place to ensure proper tracking, usage, and manage of the oil inventory.

- Customized Report – Enhance decision-making by providing clear, relevant insights to user & organization

- Compact Size and Easy Mounting – Product is designed to occupy minimal space, can be installed quickly and without complicated procedures.

- Precise Dispensing – Essential for optimizing processes, reducing costs, and ensuring quality outcomes

How CLMS Benefit Workshops

Lube Oil management system is designed to increase the efficiency of the oil change process and provides full visibility on the quantity of oil dispensed.

The modular design facilitates integration into new or existing workshops, which increases efficiency and productivity of the service station.

- Handling and transferring oil from one container to another or to engine without wastage.

- CLMS is Electronically controlled intelligent modular unit provides precise metering and dispensing of oil for automotive and industrial application.

- The meter Modules provides fast response to electronic commands and ensures precisely controlled preset dispensed volume.

Centralized Lubrication Management System (CLMS) Benefit at Workshops

- Improved Efficiency: Streamlines the lubrication process by automating the delivery of lubricant to multiple points, reducing manual labor and time.

- Cost Savings: Minimizes lubricant waste through precise dispensing and reduces labor costs related with manual lubrication.

- Consistent Lubrication: Ensures that all machinery receives the proper amount of lubricant, improving performance and extending equipment life.

- Enhanced Equipment Reliability: Regular and accurate lubrication helps prevent breakdowns and reduces maintenance costs.

- Centralized Monitoring: Provides real-time data and analytics on lubrication practices, enabling better decision-making and proactive maintenance.

- Safety Improvements: Reduces the risk of accidents associated with manual lubrication tasks and helps maintain a cleaner work environment.

- Environmental Benefits: Reduces spillage and waste, contributing to more sustainable operations.

Models & Configuration of Centralized Lubrication Management System

| MODEL | CONFIGURATION |

|---|---|

| CLMS – 1 Dispensing Point 2 Grade of Oil | Keypad – 1 Flow Control Valve – 2 Hose Reel – 2 Gun – 2 Oil Pump – 2 |

| CLMS – 1 Dispensing Point 3 Grade of Oil | Keypad – 1 Flow Control Valve – 3 Hose Reel – 3 Gun – 3 Oil Pump – 3 |

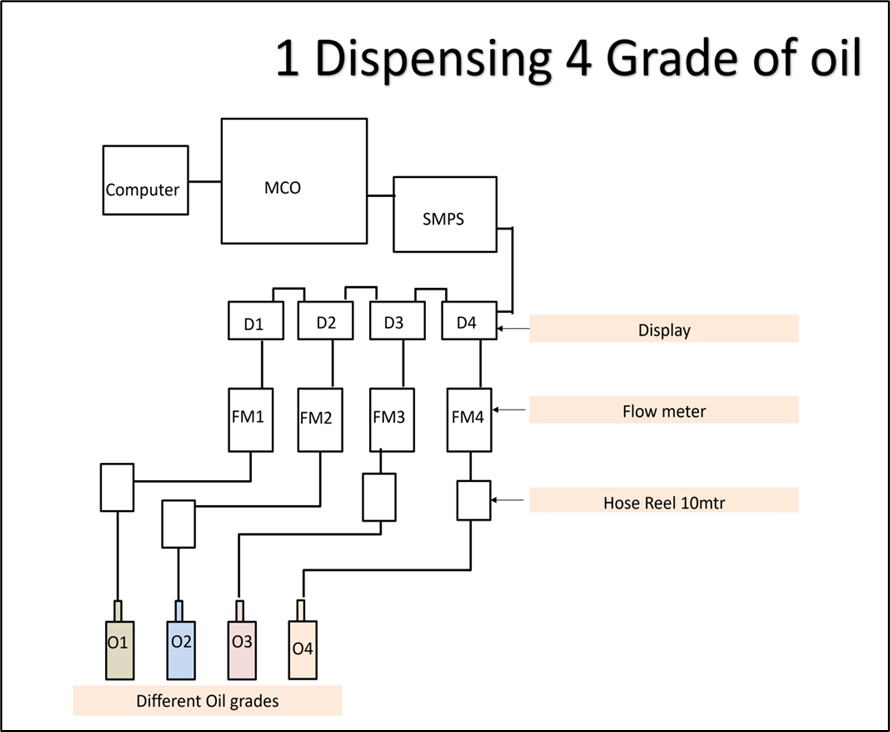

| CLMS – 1 Dispensing Point 4 Grade of Oil | Keypad – 1 Flow Control Valve – 4 Hose Reel – 4 Gun – 4 Oil Pump – 4 |

Conclusion

Centralized Lubrication Management System, CLMS ensures consistent and accurate oil change process, minimizes downtime, and enhances workplace efficiency. Investing in a CLMS is a proactive step toward more sustainable and efficient maintenance practices, ultimately contributing to greater productivity and a stronger bottom line.