Collision Repair System

Chapter 1: About Autorobot – Collision Repair System (CRS)

Outstanding Results to Car Body Repair Work

Collision repair system is versatile and universal equipment used for car body repairs. These systems are equipped with drive-on ramps and a scissor lift, making car fastening quick and easy. The structure of the straightening bed is specially designed to provide easy access to the vehicle chassis for tasks such as straightening, measurements, re-assembly, servicing, and other repair jobs on the car.

About Collision Repair

Collision/ Crash Repair is a service that has been used in the automotive industry for many years. It’s used to repair damage caused in vehicles during collisions. Collision repair is unique in that it allows for damaged vehicles to be repaired and returned to full functionality without the use of new materials

What is the advantage of repair?

Replacement costs can be significantly reduced by restoring worn components rather than replacing them. This is especially the case when the damage or wear is limited in areas(as OEM recommended).

The future of collision repair hinges upon the capacity of industry professionals to innovate and enhance the quality, integrity, and durability of components. Crash repair experts must also continue in their quest for innovation to assist customers in economizing while acquiring newer, technologically advanced vehicles. Through progress and innovation, collision repair professionals will persist in reshaping how consumers perceive the automotive industry.

Chapter 2: Collision Repair System – Damage Assessment & Inspection

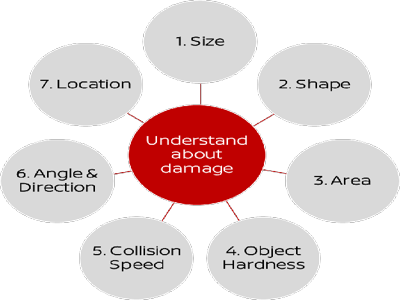

Factors of Damage Assessment

To better diagnose, develop and execute a proper repair plan once a car is damaged in a collision, a technician needs to be able to understand not only how the collision affected the point of impact, but also how the collision energy transferred throughout the vehicle.

CRS is a complete Body repair system capable of handling all types of vehicle bodies. It can repair small, medium and heavy damages.

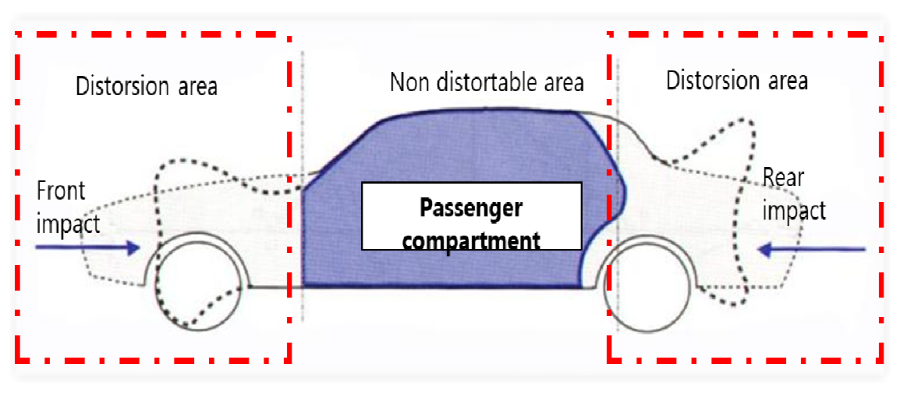

Importance of Crumble Zone

To absorb the impact energy, the distorsion areas are made of integrated zones which can fold in case of damage called as Crumble Zone

Damage Inspection

Assume that every accident is different, so it is vital to first determine

- The Damage area

- The Depth of the Damage

- The Extension of the Damage

How can we Inspect Damage

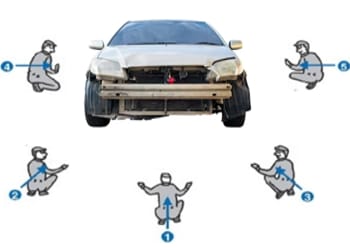

Chapter 3: Collision Repair System – Vehicle Loading

LOADING A CAR INTO A CRASH REPAIR SYSTEM

Below steps to ensure safe and efficient handling of the damaged vehicle.

- Safety Precautions

- Vehicle Assessment

- Prepare the Repair System

- Secure the Vehicle

- Careful Maneuvering

- Mount the Vehicle

- Begin Repairs

Remember that loading a car into a crash repair system should be done by trained professionals who are familiar with the specific equipment and safety protocols in the repair shop. Safety is paramount, both for the personnel involved and for the vehicle being repaired

Safety Precautions :

- Ensure that the repair area is clear of any obstacles or hazards

- Make sure all personnel involved in the loading process are wearing appropriate safety gear, including gloves and safety glasses.

- Confirm that the repair system, such as a frame rack or lift, is in proper working condition.

Vehicle Assessment :

- Examine the damaged vehicle to assess the extent of the damage and determine the best approach for loading

- Identify any critical structural damage that might affect the loading process.

Prepare the Repair System :

- Position the crash repair system, whether it’s a frame rack, alignment bench, or lift, in a way that allows for easy access and safe loading.

- Ensure that the system is level and stable

Secure the Vehicle :

- Use appropriate lifting equipment, such as a forklift or a car dolly, to lift the damaged vehicle

- Attach straps or hooks to secure the vehicle to the lifting equipment. Be careful to avoid further damage to the car’s structure.

Careful Maneuvering :

- Slowly and carefully move the vehicle onto the repair system, ensuring that it aligns properly with the system’s anchor points.

- Use a spotter or guide to help navigate the vehicle into the correct position.

Mount the Vehicle :

- Once the car is in position on the repair system, secure it using clamps, chains, or other appropriate anchoring methods

- Ensure that the vehicle is firmly held in place to prevent any movement during the repair process.

Begin Repairs :

- With the car securely loaded on the repair system, you can now start the necessary repair work, which may include straightening the frame, replacing damaged parts, and refinishing the vehicle.

Chapter 4: Features & Benefits of Collision Repair System

The system is equipped with:-

- Drive-on ramps and scissor lift, which make car fastening easy and quick.

- Structure of the straightening bed is specially designed for easy access to vehicle chassis for straightening, measurement, re-assembly, service and other repair jobs in the car (vehicle) chassis.

Features

- Lifting Bench : Powered with 10 Ton capacity pneumatically operated hydraulic pump with locking provision and wheels.

- Ramps : Galvanized panels with stands and it is detachable.

- Bench : Powder coated MS material and can be detached.

- Pulling tower : Made of special aluminum can be fixed all around the bench and from each point it can cover 70 % of the vehicle.

- Sill clamps : By tightening single bolt it will hold the car and also itself gets tightened to the bench.

- Pulling tower pump : Pneumatically operated, Hydraulic pump of 10 ton capacity.

Benefits

- Save time

- More rotation of funds

- Customer delighted

- There is less fatigue

- Technician desire

Chapter 5: Collision Repair System – Application

Application

- Sideways Pulling

- Upward Pulling

- Downward Pulling

Autorobot Crash repair system is ready for quick pulls to all directions (sideways, upwards/downwards).

The “pulling process” in the context of a crash repair system typically refers to a part of the repair process where damaged or misaligned vehicle components, particularly the frame or structural elements, are realigned or “pulled” back into their proper position. This process is essential in collision repair to ensure that the vehicle’s structural integrity and alignment are restored to OE specifications.

- Assessment : The first step in the pulling process is to thoroughly assess the extent of the damage. Technicians use various tools and measuring equipment to determine the misalignment and damage to the vehicle’s frame and structure.

- Frame Straightening : If the frame or structural components are damaged or misaligned, the repair facility will use specialized equipment such as frame racks and hydraulic pulling systems to gently and precisely apply force to straighten and reshape the damaged areas. This can involve pulling, pushing, and bending the metal to return it to its original shape.

- Mounting and Clamping : The damaged vehicle is securely fixed to the frame rack or pulling system using specialized clamps and fixtures to prevent any movement during the pulling process. This ensures that the force applied is directed precisely to the damaged areas.

- Pulling and Measuring : Technicians use hydraulic pulling tools and measuring systems to carefully apply force to specific points on the damaged components. During this process, they continually measure and check the alignment of the vehicle to ensure it matches the OE specifications.

- Verification : Once the pulling process is completed, technicians verify that the vehicle’s structure is aligned correctly. They use measuring systems and alignment equipment to ensure that the repaired components match the OE specifications.

The pulling process is a critical step in collision repair, as it helps ensure the structural integrity and safety of the vehicle. Skilled technicians with specialized training and equipment are typically responsible for performing this task to restore the vehicle to its original condition.

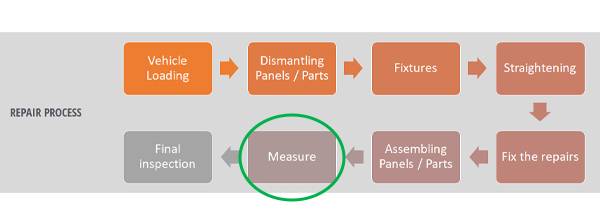

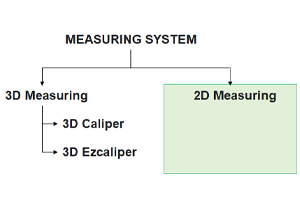

Chapter 6: Measuring System

Measuring system assists you with chassis and upper body straightening work by telling the direction and extent of straightening

Why Measuring System?

Measuring tools are crucial in an automotive workshop as parts must meet specific tolerances to ensure proper functionality and durability under various stresses.

The measuring system in a body shop serves several important purposes:-

- Accurate Repair Assessment

- Alignment Verification

- Quality Control

- Enhanced Efficiency

- Customer Satisfaction

Accurate Repair Assessment :

Measuring systems help assess the extent of damage to vehicles involved in accidents or collisions. By precisely measuring dimensions and alignments, technicians can determine the areas that require repair or replacement.

Alignment Verification :

These systems ensure that repaired or replaced components are aligned correctly with the vehicle’s original specifications. This is crucial for maintaining structural integrity, safety, and overall performance.

Quality Control :

Measuring systems aid in quality control by verifying that repairs meet original manufacturer specifications(OEM). This helps ensure that vehicles leaving the bodyshop are safe and adhere OEM dimensions.

Enhanced Efficiency :

Utilizing measuring systems can streamline repair processes by providing technicians with accurate data upfront, reducing the need for trial and error during repairs. This efficiency can lead to faster turnaround times for customers.

Customer Satisfaction :

By using precise measuring systems, Bodyshop can deliver high-quality repairs that meets exceed customer expectations. This can enhance customer satisfaction and reputation, leading to repeat business and positive referrals.

Overall, the measuring system in a body shop plays a vital role in ensuring accurate, efficient, and high-quality repairs, ultimately benefiting both the users.

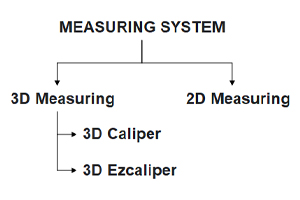

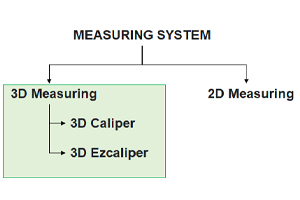

Chapter 7: 3D Measuring System

3D Measuring system can measure three surfaces; length, width, and height.

3D Measuring system is an advanced measuring device for exact verification of vehicle chassis and body condition and for damage documentation.

With Autorobot’ s easy-to-use measuring system car chassis and body measuring is very efficient. Mechanical 3D measuring system consists of the mechanical device for car chassis and of the measuring arch moving over entire car body.

Autorobot 3D measuring system you can measure both car upper body and chassis with great efficiency. Measuring system assists you with chassis and upper body straightening work by telling the direction and extent of straightening. When estimating the straightening work and final result, you have with you a 3D measuring data base of chassis and upper body collected during over 30 years. Autorobot has, as the first measuring data provider in the world, included in data sheets in addition to chassis measuring data also the measuring data for example on upper measuring points of McPherson, front and rear fender corners, A-, B- and C -pillars, rocker panels and roof corners.

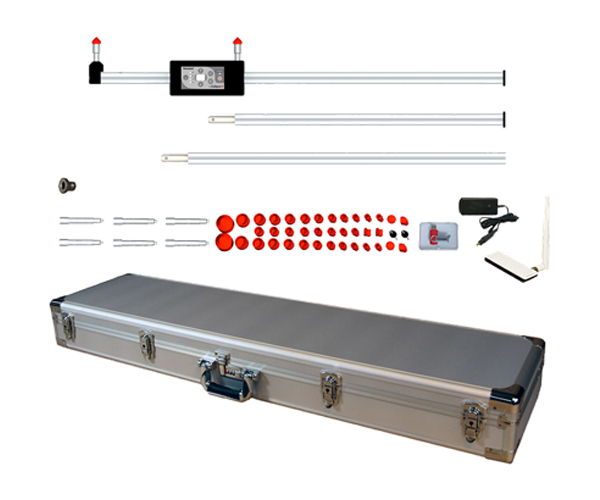

AUTOROBOT EZCALIPRE 3D

Ezcaliper is suitable for measuring passenger vehicles, cross country vehicles, and it’s most essential purpose is to serve bodyshop diagnostics and structural vehicle repair. Wireless and easily portable with the carry case, it is easy to move around. Ezcaliper is a mobile solution which adapts to the moving work of insurance company inspectors, for example. Ezcaliper provides reports from chassis and/or body points that were saved during the measuring session. It can be used for quick 2D/3D measuring in all kinds of surroundings, and therefore it opens up whole new scopes for vehicle estimation

EzCalipre is highly portable and versatile, enabling 2D/3D measuring in various environments. This flexibility expands the scope of vehicle estimation. EzCalipre’s technique is backed by Autorobot’s extensive vehicle data files, featuring approximately 60 reference points on car-specific datasheets. Utilizing wireless WLAN technology, the Autorobot EzCalipre tram gauge possesses a unique capability to measure height differences, a patented feature. Both Autorobot tram guage – EzCalipre and its accompanying measuring software, Datasheet Suite, have been in production for over 10 years.

Chapter 8: 2D Measuring System

2D Measuring system can measure two surfaces; length and width

Two dimensional or 2D shapes do not have any thickness.

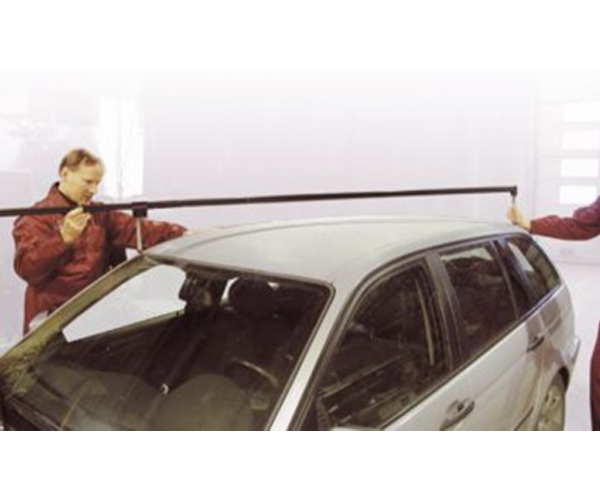

Measuring tram is an advanced 2D measuring device for exact verification of vehicle chassis and body condition and for damage documentation. The new tram can be used for 2D measuring in all kinds of surroundings.

2D MEASURING SYSTEM are a versatile and indispensable tool for determining collision damage to unibody cars and for checking critical measurements during repair. Use the tram to check dimensions between control points on suspension and mechanical components.

What is a tram gauge used for?

Tram instruments are essential tools for evaluating collision damage in unibody cars and for verifying critical measurements during repairs. They are versatile tools used to check dimensions between control points on suspension and mechanical components.

Conclusion:

In this blog chapters, we had gone through collision repair system & measuring system from Autorobot.

Application and usage with key features makes Autorobot bench unique from others.