Exhaust Extraction Systems

What are Exhaust Extraction Systems?

Exposure to hazardous vehicle exhaust emissions can cause serious health problems for you and your employees. The most efficient way to combat that exposure is to capture the exhaust fumes at the source and eliminate contact with harmful pollutants., An exhaust extraction system removes the hazardous emissions at the source.

Why are exhaust extraction systems needed for Industrial/Automotive workshops?

Exhaust extraction systems are needed to reduce hazardous exhaust emissions.They can also be used in filtration of welding fumes, grinding dust and oil mist and the removal of tobacco smoke optimising quality of indoor air.

What are the Long term Harmfulness if Not installed Extraction ?

Exposure to welding fumes and exhaust gas and toxic gas is a major concern in the industrial environment.The repeated exposure to hazardous exhaust fumes at low levels can eventually lead to health issues. An exhaust extraction is necessary to maintain the safety of employees and the efficiency of machinery.

- Employees are at the risk of inhaling hazardous fumes and Gases which may lead to short term effects like Flu fume fever & long term effects like lung damage, Neurological disorder

- Exhaust gas from vehicles combine with various kind of gases decreasing the air quality

- Welding fumes generated are composed of heavy metals and various materials, which have a bad effect on human lungs kidney and heart.

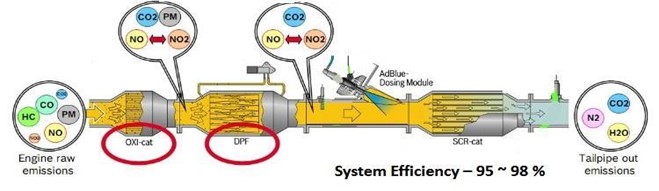

What is BS6 engine?

BSVI or BS6 is the sixth emission benchmark or criterion in reducing pollution levels when compared to the BSIV or BS4 emission norms. Both are the maximum emission norms which set the maximum pollution from the exhaust of the motor vehicle. … Compared to the BS4, the BS6 fuel has less sulphur and NOx.

Bharat Stage (BS)- 6 Diesel Engine Overview

- Real Driving Emission (RDE) determines the real-time vehicle emission available in BS6 vehicles

- Onboard Diagnostics (OD) is mandatory for all BS6 vehicles

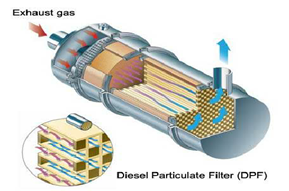

- Diesel Particulate filter (DPF) & Selective Catalytic Reducer (SCR) introduced in BS6 engine

- NOx levels will be brought down by considerably in BS6 diesel engines

- BS6 grade fuel has 5 times lower sulphur content than BS4 fuel.

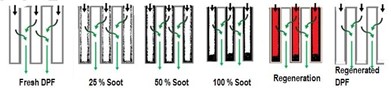

What is Regeneration Process?

The process of burning the Particulate Matter (Soot) accumulated in the DPF is called Regeneration.Soot is a by product of incomplete combustion when the air & fuel mixture that powers the engine fails to completely ignite to produce its energy potential

Methods of doing Regeneration

Passively: (Depending on engine rpm in highways) Automatically happens when the vehicle is running on a long way

Actively: (At the Regeneration Bay in service stations: partially/fully choked condition of Diesel Particulate Filter)

Basics of Exhaust Extraction System

Exhaust extraction systems mainly consist of extractor assembly, hoses & nozzles mounted above the vehicles in service centres. The nozzles are easy to attach to the exhaust pipe of the vehicle. During regeneration at the engine bay, where the hoses will extract the fumes and prevent them from spreading to the service personnel.By extracting the Toxic Gases & reducing the temperature considerable to ambient conditions, EES makes the environment safe & workable

Application of Exhaust Extraction System

EES is used in Regeneration Bay & Engine Bay of vehicle service centres. However there are few differences in the application.

Regeneration Bay is a bay dedicated for doing regeneration activity for BS6 vehicles where engine runs at higher RPM (45mins to 1 hour) and Engine Bay is a separate bay for performing engine tuning/ replacement of parts where noise & exhaust emissions are commonly generated.

| EES for Regen Bay | EES for Engine Bay | |

| Types of Hoses | 2 types(depending on model) | 1 type of hose |

| Temperature Resistivity of Hoses | 2 types of hoses: 700ᴼC +500ᴼC 700ᴼC | Not more than 200ᴼC |

Importance of EES during Regeneration Process

- Exhaust gas temperature reaches anywhere between 600ᴼC to 700ᴼC and would be impossible for the operators to stand near surrounding bay area due to the high temperatures

- Soot is burnt and ashes are thrown out from the exhaust pipe for a period of 45 minutes to 1 hour (depending on the choke in the DPF)

- High risk of inhaling toxic fumes by the operator

- EES makes the bay environment breathable & safe for the service personnel by extracting the exhaust fumes away from the bay