QUALITY FINISH PAINTING IN YOUR VEHICLE

A paint drying system is a vital component in the world of automotive finishing and industrial painting. It’s the technology that transforms freshly applied wet paint into a durable, flawless finish. Let’s dive in deeper about the paint curing system that you should actually need to know.

Paint ‘drying’ happens when the solvents evaporate from your paint coating, leaving the paint feeling dry to the touch—even though it is not 100% dry. Whilst paint ‘curing’ happens when your paint coating is completely hardened and fused to the wall

Usually, the paint baking is the typical drying method for the crosslinked type paints. Currently, paint drying equipment are roughly classified into hot air convection type, radiation type, and electromagnetic wave curing type, and each method is used individually or used in conjunction.

Hot air Convection Curing type

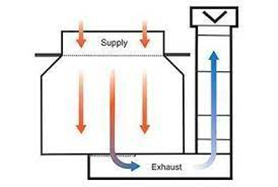

Convection is defined as the transfer of heat by circulation of a heated fluid such as air or water. In a paint curing scenario, this could include simply leaving an object to air dry with no special equipment, or it could involve the use of heated air. An example of a convection method for paint curing could also include a convection oven or a spray booth. In both examples, objects will be placed inside a relatively small area and contained area where hot air will circulate.

Infrared Curing

Of course, we are specialists with this technique! Infrared curing is where a painted surface will be positioned in front of several infrared panels. These infrared panels will then work to cure the paint with a powerful energy source. Infrared is a type of radiation energy that is invisible to the naked energy, but it is extremely powerful and can reach high temperatures, making it perfect for advanced jobs such as automotive repairs.

Infrared guarantees much shorter curing times that a lot of other paint curing techniques, especially convection methods such as air drying. Infrared paint dryer can penetrate tough surfaces and it heats up whatever surface it is facing, as opposing to heating the surrounding air.

Key reasons in Designing Your Automotive Drying Room for Optimal Curing…

- Increased Productivity

- Improve High-Quality Finish

- Environmentally Safe

What’s Special from ATS ELGI in Paint Drying System?

Taking account of ecofriendly environment, ATS ELGI offer PNG Burner Baking system incorporating in our Paint Spray Booths.

PNG – Commonly referred to as the GREEN FUEL because of its lead and Sulphur free character and minimize the emission of harmful gases emitted to the atmosphere

Benefits of our Automotive Paint Drying System:

- Highly efficient

- Reduces Carbon monoxide emissions by 90 – 97%

- Eco friendly

- Low maintenance

- Low running cost

- It is lighter than air, so in case of leak it just rises and disperses into the atmosphere and mixes in the air easily and evenly

Conclusion

Being a leading automotive garage equipment manufacturer, continue to drive progress in the automotive industry, offering solutions that enhance productivity, reduce downtime, and provide the necessary tools for technicians to excel. Know more about our Body Shop Equipment products at our website or reach us at our toll free number 1800 203 3544 for enquiries.

References:

https://www.spraysystems.com/wp-content/uploads/Drying-Room-Automotive_2021.pdf

https://infratech-solutions.co.uk/what-paint-curing-is-and-the-techniques-you-can-use/