SPRAY PAINT BOOTH PART-1

With more than 60 years of experience ATS ELGI has installed around 3500 paint spray booths across the globe. The R & D experts of ATS ELGI have been carefully designing and developing paint spray booths for automotive and other industrial applications such as furniture, commercial vehicles and other manufacturing industries. It is always very important to check twice before selecting a paint booth as it may result the organization in direct cash loss due to unnecessary running costs or it may not be sufficient enough to cater your load and exact requirements.

At ATS ELGI we create custom booths specific to your needs and ensure you meet the requirements.

Why to Choose a Paint Booth

Paint spray booths are vital for any finishing industry. A high quality paint booth will help to give a professional finish to the automobiles. Learn more about why spray paint booths are a requirement in any finishing industry.

- Controlled Environment for Effective Painting

- Control Hazardous Materials

- Clean Painting Environment

In any method of coating or spraying, there are a plenty of factors that affect the outcome of the product. Common concerns are temperature, humidity, dust and other environmental factors. A spray paint booth creates a controlled environment and eliminates these concerns. It helps in higher productivity and quality finish. The baking system helps paint and other coatings dry faster. A good lighting within the booth ensures accurate colour matching and any finish issues such as debris, blemishes are easier to see and address. The quality of the air inside the paint booth affects the safety and the operational performance. Fumes and particles pose a threat to the health of the operating staff. A spray booth accompanied with a filter can eliminate hazardous materials and keep the quality of air clean. A spray booth provides a place that is free from dust, debris. This ensures longevity of the finished products.

Choosing the right Spray Paint Booth

A paint booth is a ventilated space that enables staff to work in hygienic condition. Learn more about the significant factors to be considered to choose a paint booth.

Structure of a Paint Booth

Structure of a Paint Booth

A paint booth is made of panels that channel the air, a fan unit that helps in circulation of the air within the booth and helps in keeping the air clear, an extraction chimney and an electric control cabinet. In addition to the basic structure of a paint booth ATS ELGI provides metal base booth, parts hangar, diesel tank, a diesel tank stand and vehicle entry ramps.

Size

Size

The dimension of the biggest part of the vehicle / object including trolley or pallet that requires painting needs to be considered. Then add 3 feet to the length and 5 feet to the width to determine the size of the booth. A filter is an essential part that helps prevent exiting fumes polluting the air. It is important to monitor the booth filters to eliminate performance losses.

Filtration

Filtration

A filter is an essential part that helps prevent exiting fumes polluting the air. It is important to monitor the booth filters to eliminate performance losses.

Lighting

Lighting

A good lighting will give the best possible view of the painting. This helps in ensuring the overall finish of the product. A variety of LED lighting options are available with ATS ELGI.

Heating

Heating

To keep the proper air pressure in the paint booth, the exhausted air during operation needs to be replaced. An air make- up unit does this job and it provides the best environment for the operator and produces the best paint job.

Fans

Fans

The direct shaft mounted blowers without the use of pulleys or belts ensure adequate air velocity during operation. In addition to its specially designed blowers, ATS ELGI offers variable frequency drives capable of controlling different air volumes.

Electricity Expenses

Electricity Expenses

The amount of electricity expense needs to be factored while considering a spray paint booth. ATS ELGI provides inverters backed by VFD technology that helps in reducing energy consumption. These inverters avoid jump start of motors thereby avoiding peak amps.

Ventilation

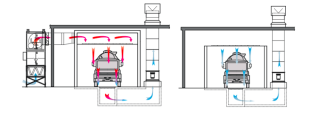

Ventilation

Downdraft paint booth provide the best airflow style for controlling overspray and contamination compared to other direction of flow of air. In downdraft paint booths, air enters through a filtered ceiling plenum in a downward motion, flows vertically over and around the product, and exits through a filtered exhaust pit in the floor that runs nearly the entire length of the paint booth. ATS ELGI provides downdraft paint booths that are excellent for reducing touch-up costs and improving production time.

Safety Guidelines

Properly designed and operated spray booths provide an efficient way to control ventilation, minimize exposure to hazardous materials and contain aerosolized flammables. To ensure worker safety, several steps should be taken when designing and using spray booths.

- Spray booth construction with fire resistive materials

- Providing Enough ventilation

- Electrical Precautions

- Preventive Maintenance

ATS ELGI provides a smart control panel that has a graphic LCD screen, designed with safety interlocks, alarms (filter replacement, motor overload), Error Messages.

What makes ATS ELGI Spray Paint Booths Different

ATS ELGI is committed to providing best paint booths. We offer top-quality materials and offer wide range of customized options. Choosing the right paint booth involves more than just picking the dimension and features that are wanted. You should also be considering:

- Safety of the operators

- Quality of the painting work

- Productivity

- Eco friendliness

Spray paint booth from ATS EGI meets all these requirements. Whatever your unique needs and requirements are, ATS ELGI has a booth waiting that can attract more business and promote a safer work environment.