Spray Paint Booth – Part-3

Over 30 years of automotive paint booth engineering brings you unmatched build quality and unstoppable performance.

There are various types of paint booths sold for a wide range of purposes. Paint booths can be used for artistic purposes, such as for painting a sculpture, and they are also commonly used to paint cars, vehicles, aeroplanes, trucks and other modes of transportation. The purpose of a paint booth is to control the environmental conditions while an object is being spray-painted. Automotive paint booths use extraction fans and specialized ventilation systems to remove chemical fumes from strong paints as well as dust particles, overspray and other contaminants that can affect the paint job. Paint booths can also regulate the temperature and humidity within the area, which allows the paint to be applied properly. Using a paint booth with heating technology can also bake the paint job in order for it to cure quickly and efficiently, which reduces the risk of scratches and other damage to the surface of the product.

There are various styles of paint booths available on the market and the type of booth you choose for your facility depends on many factors. The shop size, the volume of jobs to be done per day and the types of vehicles you will be painting will all help you to determine the right paint booth for your shop. Whether you are looking for a fully heated, high-production paint booth or a simple non-heated booth with basic features [1].

Types of Spray Booths

Like everything else in manufacturing, you can find a spray paint booth designed for your particular application. You’ll find models intended for small plastics, furniture, motorcycles, automobiles, aircraft, boats and more.

Open Face Spray Booths

These models include a ceiling, two sidewalls and a rear exhaust plenum. Air flows through the open front and out through the rear exhaust system. Open-type booths are popular choices for woodwork and finishing furniture. You also find these booths in auto facilities, from manufacturing to repair centres.

Pressurized Booths

This is an enclosed spray booth that exhausts air outdoors at the same volume at which it draws in air. An air makeup system or heater is used in the colder environment to aid temperature control and air purity. This is a popular style for manufacturing and refinishing automobiles and electronics, where a clean environment is a vital component of finish quality.

Non-Pressurized Booths

This system draws air from and expels it into the building via a series of filters. Some environments require a heated air makeup unit. Manu industries use non-pressurized spray paint booths, including auto manufacturing and refinishing, metalwork and fibreglass.

The Main Types of Automotive Paint Booths

There are four main types of automotive paint booths to choose from including a cross draft booth, semi-downdraft, side draft and downdraft.

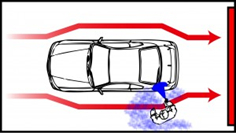

Cross draft

A cross-draft paint booth allows the air the flow directly across the vehicle that is being painted. These are extremely popular in the automotive and truck industry because they are economic and they easily meet all the standards and codes for a painting facility. The way a cross-draft paint booth works is that the incoming air is drawn directly through the main doors or through filtered columns in the front corners of the paint booth. The exhaust is accomplished through another set of columns located towards the rear of the paint booth. The air basically circulates around the sides of the vehicle. Cross draft booths are constructed with the least amount of materials than any other paint booth, meaning they are offered at a lower cost and they also don’t need any concrete work.

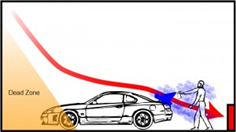

Semi Downdraft

A semi-downdraft paint booth operates much like the cross draft because the exhaust is still achieved through the rear of the paint booth. The main difference is that the incoming air is now coming in through a small section in the ceiling, which is located at the front of the paint booth. This creates a diagonal draft pattern that moves contaminants away from the vehicle being painted. The main disadvantage of the semi-downdraft booth (as well as the cross draft) is that the painter is most likely going to be standing in the way of the draft and will be exposed to more overspray than need be.

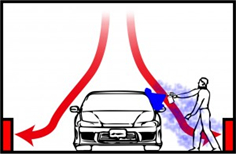

Side Draft

A side draft paint booth operates by bringing in filtered air through the ceiling and exhausting it through the sidewalls of the workspace. This style creates an even airflow around the painted object and draws overspray and contaminants down and away from the finish, which makes for a cleaner environment and a more efficient paint job. In terms of materials used for construction, a side downdraft booth is the most expensive to manufacture.

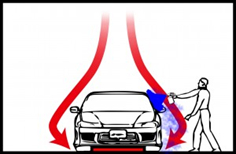

Downdraft

A downdraft paint booth produces a draft pattern that runs straight down from the ceiling to the floor and is the most efficient and clean option. Since the air is drawn around the vehicle and exhausted under the object, it pulls overspray and contaminants downward and away from the object no matter where the operator is spraying. The risk of overspray and contamination is also greatly reduced for the painter. The only disadvantage to a downdraft paint booth is that it requires a concrete pit or it needs to be raised on steel basements with drive-up ramps to make room for the downdraft to function.

References

https://www.accudraftpaintbooths.com/products/automotive-paint-booths/

https://www.accudraftpaintbooths.com/blog/choosing-the-right-paint-booth-for-you/