Vehicle Suspension Test and it’s importance

What Is A Suspension?

We get asked this question by many car enthusiasts. Although some experienced car lovers know the answer, it is never a bad idea to revise it. Simply put: the car suspension absorbs the shocks and pushes the wheels toward the ground when they lift up after a speed or road bump. This essential part of each vehicle usually consists of tires (and tire air), springs, shock absorbers, and the linkages connecting the car body to the wheels. Without all these car suspension parts, it would be impossible to speak of ride quality or road handling. However, sometimes people tend to overlook the importance of the car suspension system.

But even a Victorian-era carriage has a suspension-like system and we all know the rough ride they offer. Now imagine the same ride but with your car, developing much higher speed than the speed of a pair of horses. Without the modern suspension type, a bone-breaking bumpy ride is guaranteed every time you sit behind the wheel. But that’s not all, since even the overall driving will be extremely dangerous. Imagine what will happen when you take a sharp turn: the inside wheels will lift off the ground, resulting in a side roll. So, testing your suspension in a regular manner with the suspension testing equipment will ensure the safety of your vehicle.

Link : https://auto.howstuffworks.com/car-suspension.htm

Types of Suspension system:

The Most common suspension system in the automotive section are the following,

- Coil Spring.

- Leaf springs.

- Torsion bars.

- Air springs

Coil springs are the most common type of spring and is, in essence, heavy-duty torsion bar coiled around an axis. Coil springs compress and expand to absorb the motion of the wheels.

springs consist of several layers of metal (called “leaves”) bound together to act as a single unit. Leaf springs were first used on horse-drawn carriages and were found on most American automobiles until 1985. They are still used today on most trucks and heavy-duty vehicles.

Torsion bars use the twisting properties of a steel bar to provide coil-spring-like performance. This is how they work: One end of a bar is anchored to the vehicle frame. The other end is attached to a wishbone, which acts like a lever that moves perpendicular to the torsion bar. When the wheel hits a bump, vertical motion is transferred to the wishbone and then, through the levering action, to the torsion bar. The torsion bar then twists along its axis to provide the spring force. European carmakers used this system extensively, as did Packard and Chrysler in the United States, through the 1950s and 1960s.f springs consist of several layers of metal (called “leaves”) bound together to act as a single unit. Leaf springs were first used on horse-drawn carriages and were found on most American automobiles until 1985. They are still used today on most trucks and heavy-duty vehicles.

Air springs consist of a cylindrical chamber of air positioned between the wheel and the car’s body and use the compressive qualities of air to absorb wheel vibrations. The technology is used in many luxury vehicles today, but the concept is actually more than a century old and could be found on horse-drawn buggies. Air springs from this era were made from air-filled, leather diaphragms, much like bellows; they were replaced with molded-rubber air springs in the 1930s.

Important of car Suspension:

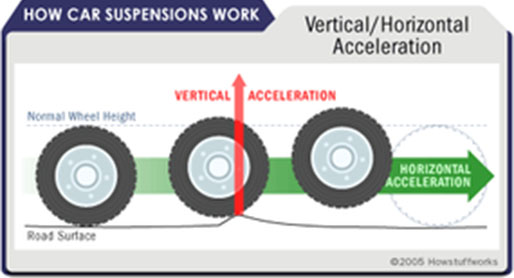

If a road was perfectly flat, with no irregularities, suspensions wouldn’t be necessary. But the roads are far from flat. Even freshly paved highways have subtle imperfections that can interact with the wheels¬ of a car. It’s these imperfections that apply forces to the wheels. According to Newton’s laws of Motion, all forces have both magnitude and direction. A bump in the road causes the wheel to move up and down perpendicular to the road surface. The magnitude, of course, depends on whether the wheel is striking a giant bump or a tiny speck. Either way, the car wheel experiences a vertical acceleration as it passes over an imperfection.

The suspension on your car maximizes the friction between the tires and the road and provides steering stability. Without an intervening structure, the wheel’s sheer energy is transferred to the frame, which moves in the same direction. In such a situation, the tires can lose contact with the road completely. Then, under the downward force of gravity, the tires can slam back into the road surface. What you need is a suspension tester which provides the suspension of your vehicle, the suspension tester that will absorb the energy of the vertically accelerated wheel, allowing the frame Handling: a car’s ability to safely accelerate, brake and corner.